Model: LD-300A/430A

Packaging materials: Multilayer Composite Premade Bag(e.g.: PET/PE).

Bag Type: 3-side-seal, gussette pouch, standup pouch no-zip-lock.

Sealing Type: Straight grain, pitch is 1mm (Optional reticulate).

1-15 bags/min

Model: LD-300A/430A

Packaging materials: Multilayer Composite Premade Bag(e.g.: PET/PE).

Bag Type: 3-side-seal, gussette pouch, standup pouch no-zip-lock.

Sealing Type: Straight grain, pitch is 1mm (Optional reticulate).

1-15 bags/min

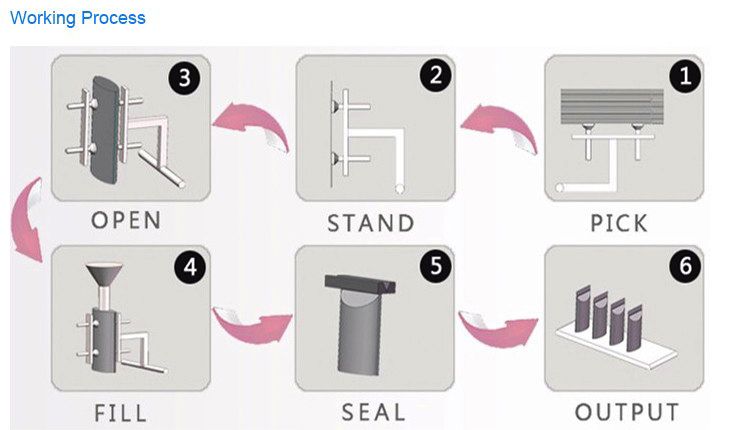

● Introduce: It can auto finish material feeding, weighing, premade pouch pick-up, open, fill and seal, etc. Premade pouch can be 3-side-seal, gussette pouch, standup pouch no-zip-lock.

● Application: Suitable for various granlue material in premade pouch style, such as candy, beans, nuts, dry fruits, cereal, chocolate, biscuit, peanut, capsule, seeds, chemicals, sugar, etc.

● Kindly Reminder: We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Basic Configurations:

● Touch Screen: China Kinco 7 inches corlor touch screen;

● Languages: Chinese, English, Spanish, Dutch, Italian, Korean (At most three languages);

● PLC: Japan Panasonic;

● Cylinder: Taiwai Airtac (Can be upgraded to Japan SMC);

● Vacuum Generator: China Airbest (Can be upgraded to Vacuum Pump);

● Vacuum Component: Japan SMC;

● Modular Control System For Vacuum Pressure: Japan SMC;

● Modular Control System For Temperature: China YUDIAN;

● Electrical Component: Schneider / Omron;

● Safety Key Interlock Switch;

● The main structure of the machine is SUS304 (The thickness of the rack is 3.0mm), and the material of the part is aluminum;

● The part (Hopper) in contact with the material is SUS304 (Can be upgraded to SUS316L).

Performance Features:

● Easy to operate and easy to replace the bag / The machine is suitable for a variety of bag types;

● Low maintenance cost / Modular replacement of the parts;

● Certificate of Conformity.

Model: LD-300A/LD--430A

Bag Material: Multilayer Composite Premade Bag(e.g.: PET/PE)

Bag Type: 3 Side Seal Bag, Stand-up Bag

Upgradable Bag Type: Gusset Bag, Zipper Bag, Flat Bottom Pouch (Need additional purchase of functional device)

Size Range: 80mm≤W≤300mm 100mm≤L≤400mm

Speed: 0~15bags/min

Sealing Type: Straight grain, pitch is 1mm (Optional reticulate)

Sealing Width: 10mm (5--20mm can be customized)

Voltage: 220V, Single-phase, 50/60HZ, 1.2KW

Air Pressure: 0.65Mpa

Air Consumption: 0.3m³/min (Standard machine, no additional function)

Body Dimension: 1770*600*1260mm

Packing Dimension: 1860*710*1650mm (Export non-fumigation wooden case)

●BAG OPENINHG

Pouches are individually removed from the cartridge with a unique combination of vacuum and pneumatic actuators. They are rotated to the fill area and opened.

●TRANSITION CHUTE

doubling as a timing bucket. product enters the transition chute while the bag is being opened below. Upon pouch detection the chute enters the bag and opens its gate. Product is dispensed immediately, without spillage and protecting the seal from contamination. Difficult product that easily bridges is dispensed into the pouch directly from the filler, through the "open-gate''

●FILLING

During filling, pouches are held in place with our "posi-hold" gripper system. This allows for heavy weights and shock loads

without disturbing bag Position

●SEALING

Digitally controlled ribbed or flat constant heat seal bars give a integral attractive seal. Pouches are sealed ''in place" eliminating wrinkles, folded corners and non aligned seals

●MECHINE CONTROLS

System controls are fully solid state. utilizing a commercial Programmable Logic Controller [PLC] and pneumatics. Indicator lights signal all cycle processes for easy monitoring.

After receiving your inquiry, We will send you the quotation as soon as possible.