Model:LD-8200A/ 8240A/ 8300A

Pouch Type: All type of heat sealable preformed side seal bags, gusseted bags, block bottom bags,zip-lock recloseable bags, stand-up pouch with or without spout etc.

Filling Volume:Filling Volume:10-2500g

Packaging Accuracy:Error≤±1

25-40 bags/min

Model:LD-8200A/ 8240A/ 8300A

Pouch Type: All type of heat sealable preformed side seal bags, gusseted bags, block bottom bags,zip-lock recloseable bags, stand-up pouch with or without spout etc.

Filling Volume:Filling Volume:10-2500g

Packaging Accuracy:Error≤±1

25-40 bags/min

● Suitable for the packaging of granular items such as puffed food, snack food, frozen food, pet food, dried fruit, dried meat, nuts, beans, seasonings, etc.

● Suitable Pouches:All type of heat sealable preformed side seal bags, fin seal bags, gusseted bags, block bottom bags, zip-lock recloseable bags, stand-up pouch with or without spout ect.

Packaging Material:

coffee beans

coffee beans

coffee beans

coffee beans

coffee beans

coffee beans

Bag Style:

Zipper Pouch

Zipper Pouch

Zipper Pouch

Zipper Pouch

Zipper Pouch

Zipper Pouch

● Automatic rotary packing machine adopt precision indexing device and PLC to control each action and working station to make sure the machine operates easily and does accurately.

● The speed of this machine is adjusted by frequency conversion with the range, and the actual speed depends on type of products and pouch.

● Automatic checking system can check bag situation, filling and sealing situation.

● The system shows

1.no bag feeding, no filling and no sealing.

2.no bag opening/opening error, no filling and no sealing

3.no filling, no sealing..

● The product and pouch contact parts are adopted stainless steel and other advanced material to guarantee the hygiene of products.

●We can customize the suitable one for you according to your requiredment.

●Just Tell us : Weight or Bag Size required.

● Model: LD-8200A/ 8240A/ 8300A

● Bag Size: W: 100-300mm L: 100-450mm

● Filling Volume: 10-2500g (Depending on type of products)

● Capacity: 25-60 bags/min (The speed depends on type of products and packaging material used)

● Package Accuracy: Error≤±1%

● Compress Air Requirement: ≥0.8m³/min supply by user

Optional configuration:

1. Material weighing & filling machines

2. Platform

3. Check weigher

4. Material elevator

5. Finished product conveyor

6. Metal detector

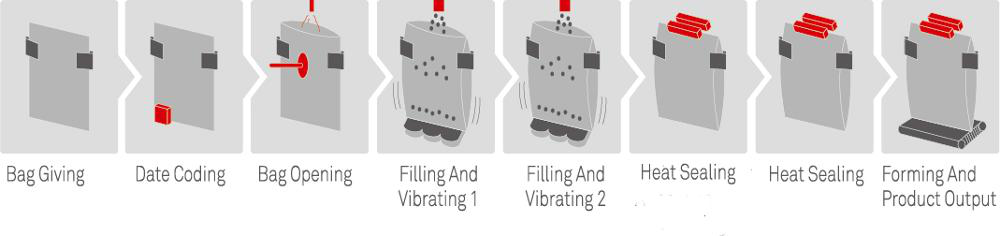

1. Bag giving

2. Date coding

3. Bag opening

4. Filling and vibrating 1

5. Filling and vibrating 2

6. Product settling after filling by vibrating

7. Heat sealing

8. Forming and product output

After receiving your inquiry, We will send you the quotation as soon as possible.