The horizontal doy pack machine replaces manual packaging and realizes packaging automation for large enterprises and small and medium-sized enterprises. The mechanical grasping equipment will automatically take the bag, print the date, open the bag, measure the signal to the measuring device and blank, seal and output.

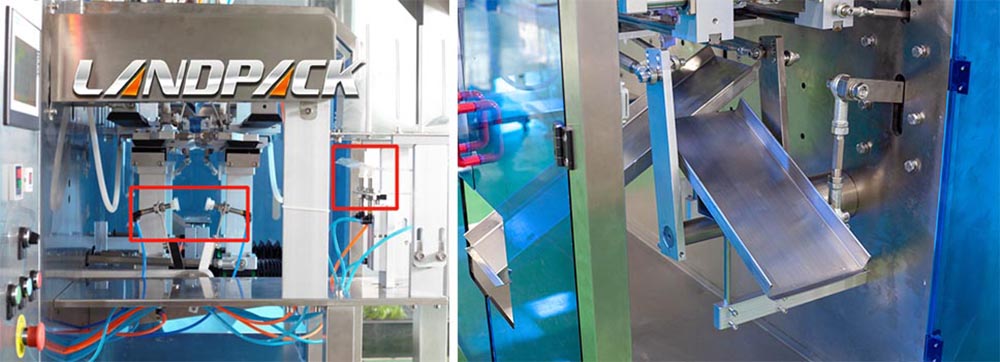

More and more customers they will add some special functions on horizontal doypack machine based on their product’s feature. Such as plastic nozzle installation. Vibrator as the feeder for plastic nozzle. Desiccant feeder,horizontal bag giving station,Inket printer etc. In a words. The whole packing process will free your hands to achieve the fully automatic packaging to increase your production and save labor cost.

Here are the main features of the horizontal doypack machine:

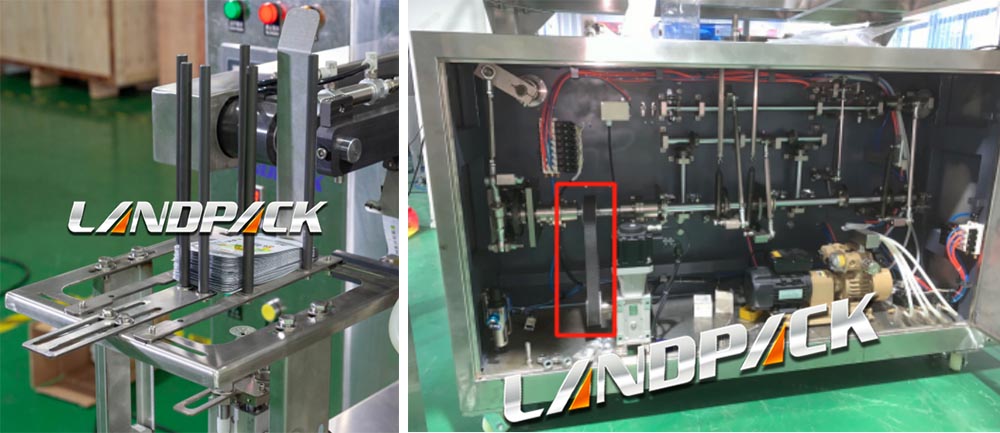

1.Easy to operate, adopt PLC control, equipped with touch screen man-machine interface control system, easy to operate

2. Frequency conversion speed regulation, the machine uses frequency conversion speed regulation device, and the speed can be adjusted at will within the specified range.

3. Automatic detection function, if the bag is not opened or the bag is incomplete, Machine will not fill material into bag. Due to the vacuum value is less than the preset value.to achieve the pre-made bags can be recycled.

4. Safety device, when the working air pressure is abnormal or the heating tube fails, it will alarm.

5. With the horizontal/Vertical bag feeding method, the bag holder can store more bags, the quality requirements of the bags are low, and the rate of bag separation and bag loading is high.

6.Some imported engineering plastic bearings are used, no need to refuel and reduce the pollution to materials;

7. Oil-free vacuum pump is used to avoid pollution of the production environment.

8.Soft connection to have stable working performance.The horizontal bag feeding machine adopts the cam structure, the cam structure runs more stably driven by servo motor ,The belt as the medium to reduce the friction and realize the stable operation of the machine. longer lifetime.

10. The loss of packaging materials is low. The machine uses prefabricated packaging bags with good packaging bag patterns and good sealing quality, thus improving the product quality.

11. In line with the hygienic standards of the food processing industry, the parts on the machine that are in contact with materials or packaging bags are processed with stainless steel or food grade material.

12. Wide range of packaging, by choosing different measuring instruments, it can be applied to the packaging of liquid, sauce, granule, powder, irregular block and other materials.

13.The packaging bag has a wide range of applications, and can be applied to prefabricated bags and paper bags made of multi-layer composite films, silica, aluminum foil, and other materials.