In the past years. LANDPACK has had the privilege of supplying automated packaging machines to companies in the cannabis industry. We understand our customers' needs as we grow with them and have built a reputation for providing innovative, reliable solutions to their cannabis and cannabis products.

We help customers package cannabis flowers, canned gummies, packaged foods, and even develop custom solutions for their CBD products. From startups to the largest multistate operator, we're known for helping companies like yours meet growing demand while reducing product waste and conserving resources.

Maybe you already have a weigh-filler, but you haven't automated the bagging process. Or maybe you're thinking about getting your first process wrapper.

Whatever your situation, before you move on, research the many benefits of a fully automated packaging system.

Why system?

Consider this example.

Let's say you need to put fondant in a container, and that container is put into a nicely designed retail carton. It sounds simple enough, but you still need to cap, seal, and label the container, and then form, fill, and close the carton.

You definitely need some automation. You might argue that some of these stages can be done by hand. Well, let's dig a little deeper.

Let's assume:

1) Dispensing too much gummy per container will cost you money, and you'd rather not risk product contamination. Result: You will need a weigh-filler.

2) Having someone put each container under the weigh fill and screw its lid on by hand might work, but it would take a lot of time. Result: You need to collect the containers, transfer them under the filling system and then through the capping machine.

3) Trying to get employees to manually seal the container is insane. Result: You need an induction sealer.

4) The curved, wrinkled labels on the container look unprofessional and it takes a lot of time to place them manually. Result: You will need a labeling machine.

5) Your cartons are too important to your retail business to trust the manual forming, loading and closing process (and also time-consuming). Result: You need an automatic carton.

Conclusion: A fully integrated container filling and handling system is the most efficient way to get your fondant ready for retail. While the front end sounds expensive, what is the cost of wasted products and hundreds of lost man-hours on the back end?

One last thought...what happens after your carton is closed? Do you need to pack them into boxes and then ship those boxes to your other locations?

If you want to save yourself more time and reduce repetitive worker injuries, we can add our all-in-one case packer/loader/sealer and robotic palletizer after the cartooning process.

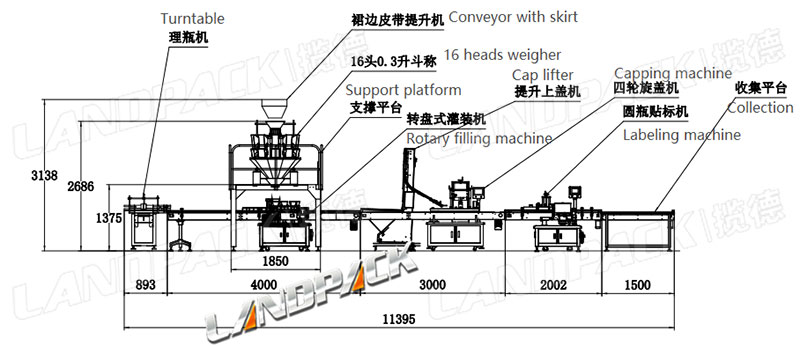

Here is a simple and standard layout of the Cannabis bottle filling line. It includes Turntable, Conveyor with a skirt to feed Cannabis. We use 16 heads weigher as the right weighing system to ensure the high weighing precision.±0.2g based on 5-10g/Jar. Rotary filling machine to increase the filling speed. Cap lifter for standard screw cap (Child-proof).A Pair clamp capping machine and a Round bottle labeling machine.

As you can see only two people are required to serve the entire packing solution. One person to feed bottles/jars on the turntable. The other person to pick up the finished bottles/jar at the last station.

No matter if you wanna bottle/jar packing solution, Roll film packing solution or Pre-made bag packing solution. LANDPACK can provide it for you!