This machine is widely used in the filling of free flow liquid, high -viscous liquid, paste and sauce products in the food industries, medicine, chemical industry, daily chemical,cooking oil, veterinary medicine, pesticide and so on. For example the cooking oil, honey, tomato sauce, chederra, seafood sauce, chili sauce, mayonnaise, peanut butter, lubricating oil, Soap liquid ,Washer detergent, hand sanitizer, shampoo, pesticides and other liquid materials. The contact part of the filling machine are made of high-quality SUS304 stainless steel which meet the GMP standards.

Special pneumatic three-way valve and filling valve are used for granular sauce materials, and the material box is designed with a stirring device to prevent the material from precipitation and solidification.

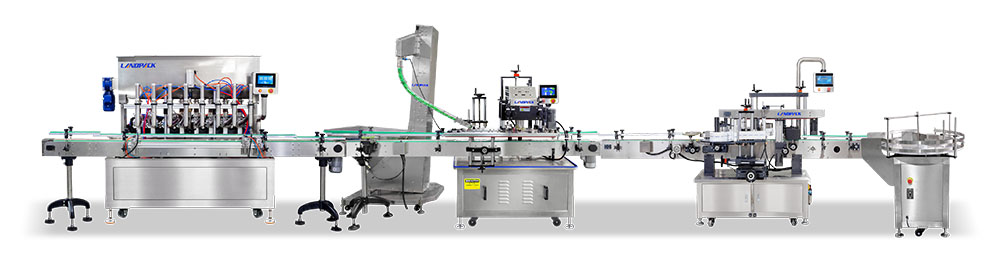

The Automatically Chili Sauce filling production line is to feed the empty bottles /cans to the horizontal filling machine for automatic quantitative filling through the bottle unscrambler, and then to the automatically cap feeder lifter, and the bottles are capped and capped by the four-wheel capping machine. Sealed and transported to the labelling machine for labelling. After labeling, it is sent to the packaging machine for boxing, and then sent to the palletizer to be stacked on the pallet, and then sent to the warehouse.

The filling production line is a filling production line composed of bottle sorting, filling, capping, labeling, etc. Its advantage is

1. High degree of automation, simple operation, stable operation, cost saving and efficiency improvement

2. Each single machine has an independent operating system, which can help enterprises achieve standardized production

3. The linkage and separation of each single machine is fast, and the adjustment is fast and simple, so that the various production processes are coordinated.

4. Each machine can used alone

5. This packaging line is designed with new technology

6. The production line runs smoothly, and the function combination and maintenance are convenient, and various production combinations can be carried out according to user needs

The performance characteristics of Landpack filling:

1. This machine adopts imported servo motor to drive the piston cylinder to realize metering and filling, and uses well-known pneumatic components, which has a long service life and is stable.

2. 3-Way valve, Simple Design ,Easy to clean

3. Equipped with automatic stirring function to make the material mixing more uniform

4. The filling head is Lande's self-innovated filling nozzle, which can effectively solve the problems of wire drawing and dripping. The filling accuracy is higher.

5. It is simple and convenient to change the specifications and adjust the filling volume directly on the touch screen;

6. Automatic bottle feeding, filling, and bottle feeding, no bottle filling;

7.Speed is 3-5bottles/min/head when filling is around 500ml.

8. The size of the bottle is easy to adjust, and it is equipped with an automatic lifting device, without the need to replace parts

9. The filling volume is accurate and has counting function;

10. Adopt PLC programmable control, with touch screen man-machine interface system;

11. The electrical components are all branded to ensure excellent quality and long-lasting stable performance

12. Sanitary valve pipeline, quick connection, easy disassembly and installation.

13. The equipment is also designed with an integrated concept, with few wearing parts, which is convenient for enterprise maintenance.

14.The Liquid Piston Pump is Horizental Saving Room Design ,if your space have limited that will be the first choice.