LAND PACK is the manufacturer specialized in all kinds of packing machines and filling machine line for more than many years experience. This passage we are going to talk about the way to do some maintenance of aluminum tube filling and sealing machine (including fully automatic and semi-automatic machine). This machine is suitable for aluminum tube filling ointment, cream, gel, paint, and some other materials products.

Sometimes we hear our customers say: my machine is too old to work. My machine couldn't fold the tube balanced when the machine is working because the tube will be folded and tilted, it cannot be on the same horizontal line so that the tube cannot seal well. The machine's using life is not so long and so on. Why do we have a lot of problems with the machine during our customer's using? The reason is because we do not maintain the machine on time and do not maintain the machine reasonably.

So how do we maintain the machine correctly? In order to maximize the service life of the equipment, necessary maintenance and maintenance must be carried out as required. There are four ways to maintain the machine.

1.Lower speed for the first time using

When we receive the new machine at the beginning, it is important for us to have the lower speed during the machine working(especially for the fully automatic machine). If the machine drives very fast as soon as it is bought back, it will damage the machine. Because when the machine is first used, the machine will have a running in transition period. After the machine run-in period, you can speed it up. The speed used at the beginning is generally 20-30 tubes/min for about 1 month is available.

2.Lubricating

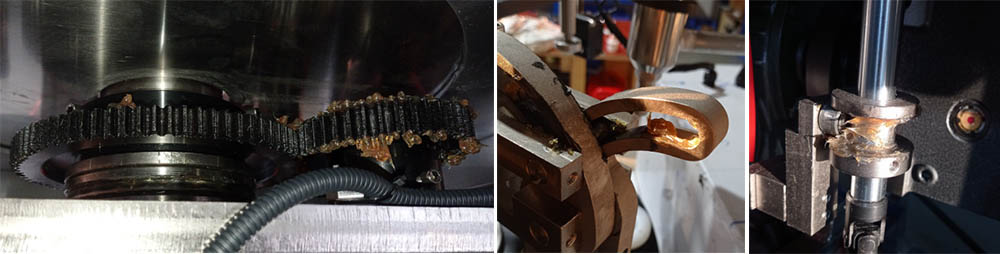

This is the most important thing to do is to add enough lubricating oil and grease in the working stations and spare parts. All parts with relative movement need to be lubricated. Oil-free bearings are used as far as possible in many movement links to this machine, and other parts still need to be oiled and greased regularly.

In particular, it is necessary to specify the pin and oil cup on the eccentric wheel of the main shaft. Grease (pin) and lubricating oil (oil cup) are required to be added once a month. In addition, the outsourcing components-reduction gearbox and cam divider should be replaced with lubricating oil regularly according to the lubrication regulations of the component.

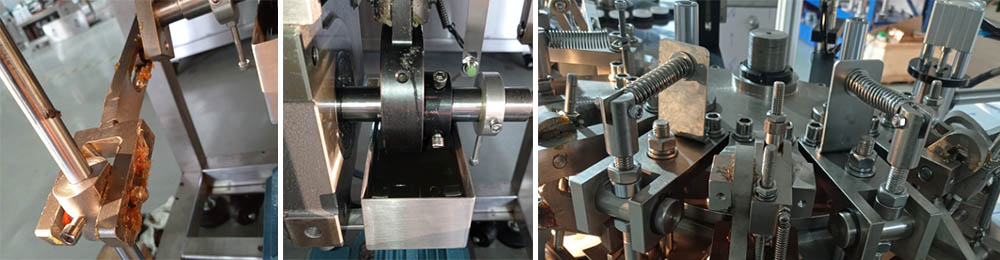

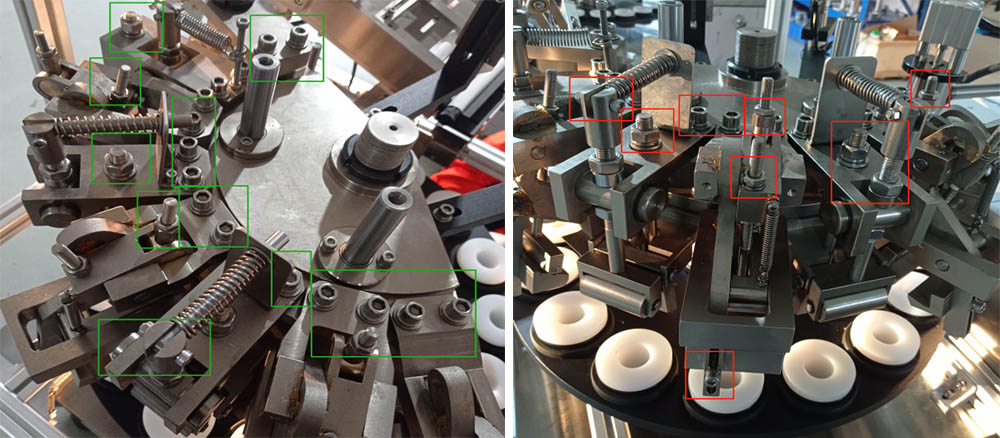

3.Checking the screws for looseness

When the machine is used for a period of time, if the screws are not checked in time, we will find that the tubes will be folded irregularly and deviated. At this time, we need to check the looseness of screws within the specified time. For example, checking the screws in every month if we find that the screws are loose. Use a horizontal ruler to test whether the folding stations are tilted. If the station is tilted, it proves that the screws of the stations are loose, so you can adjust the station and tighten the screws.

4.Cleaning

Keeping the machine cleans after using it every day. If any filling products accidentally leak to the folding stations of the machine, clean them up in time. If you don't use the machine for a long time, clean it up and put it away.

Thanks for your reading our article. We all want to prolong the service life of the machine. So let's maintain the machine in the appropriate way together!