In the context of the global epidemic, take-out meals have gradually become more frequent, and the packaging of sauce sachets has become more and more popular. Adapting to market demand, the small sachets are easy to carry and hygienic, which not only brings convenience to people's meals, but also maintains high-quality requirements for food.

Due to the large demand for the daily output of small bags of sauce packaging, manufacturers often need 20-40 sauces packing machines for packaging, which results in a large area of the machine, an increase in the number of workers operating the machine, and an increase in production costs.

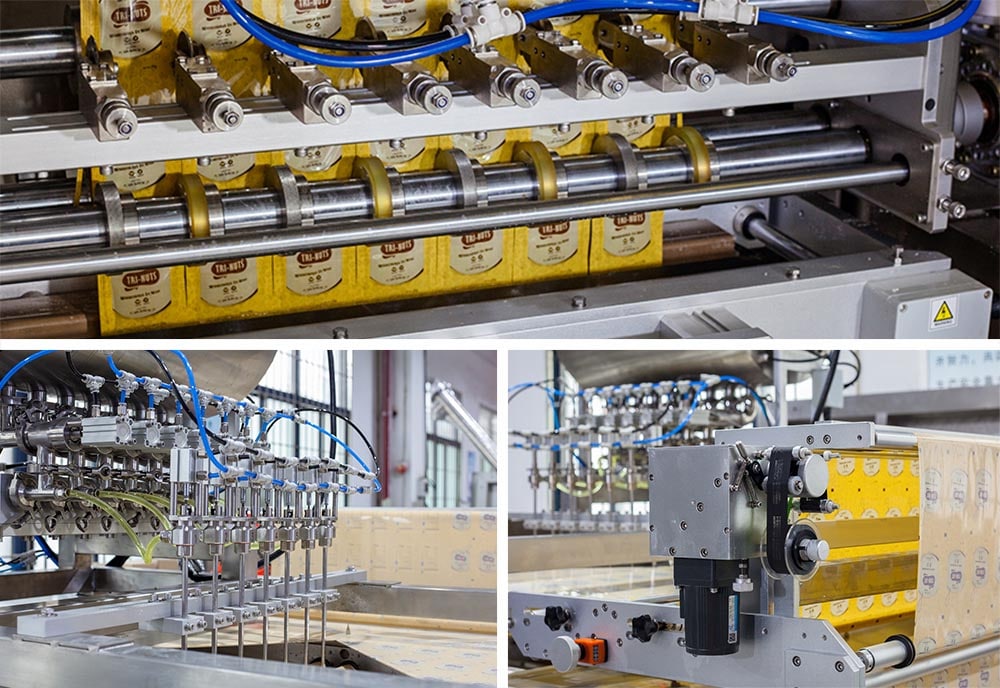

In order to help manufacturers reduce production costs, we developed and launched the sauce multi-lane packing machine. This machine can pack 4-8 bags of sauces at the same time, one machine can replaces 4-6 machines, and only one person is responsible for operating the machine. The hopper of this muti-lane packing machine has an automatic liquid level sensing function. When the hopper is not enough for sauce filling, it will give a signal to the feeding pump to automatically feed the material. The packaging machine can be automatically connected to the front-end storage bin, which is safe and hygienic from the completion of production to the packaging process. The hopper also has the function of heat preservation and stirring, which makes the sauce more evenly to fill.

The packing machine is equipped with automatic trimming function, which makes the sides of the bag more flat and beautiful. The sealing is heat-sealed with multi-lane knives, which makes the packaging more firm and beautiful, and ensures that the material will not leak during transportation.

The front and rear heat sealing are independent temperature control, the heat sealing is more uniform, the servo motor controls the bag making, the packaging is more exquisite, and the precision is high.

The filling mechanism has two capacity adjustments, total adjustment and single-channel adjustment. Each channel can independently adjust the filling capacity according to the needs, which is flexible and ensures that the weight error of each package is minimized.

The machine can also be designed with a counting function. If there is a demand for entering the box, the machine can output counting. When the output reaches the required counting, it can automatically stop for a few seconds, and then carry out the next round of packaging instead of manual counting.

The machine complies with GM safety and hygiene standards, and the humanized design can greatly reduce production costs and improve production efficiency for manufacturers, laying a solid foundation for seizing the market.