The bag automatic packaging machine instead of manual, realizes automatic packaging for large enterprises and small and medium-sized enterprises. The operator only needs to put the prepared bags and place hundreds of bags at one time on the bag taking part of the equipment, the mechanical claw will automatically take bags, list dates, open bags, measure material, seal the bag and output.It can be used to package potato chips, rice noodles, nuts, wine, soy sauce, vinegar, juice, flour, condiments, etc.

Advantages:

1. Easy to operate, using PLC control, equipped with operation screen man-machine interface control system, convenient

2. In the horizontal bag method, the bag storage device can be sent to the bag for storage and packaging, which has lower requirements on the quality of the bag, and the rate of dividing and bagging is high.

3. Open the bag so that there is a suitable bag in the pocket and avoid different styles of design

4. The loss of packaging materials is low, the quality of the documents used by this machine is good, the packaging is exquisite, and the sealing improves the defective products.

5. Meet the requirements of safe processing on food or parts in contact with packaging bags or other hygienic material processing to ensure food hygiene and food hygiene standards.

6. Wide range of packaging. By choosing different measuring instruments, it can be applied to the packaging of granules, powders, liquids, and other materials.

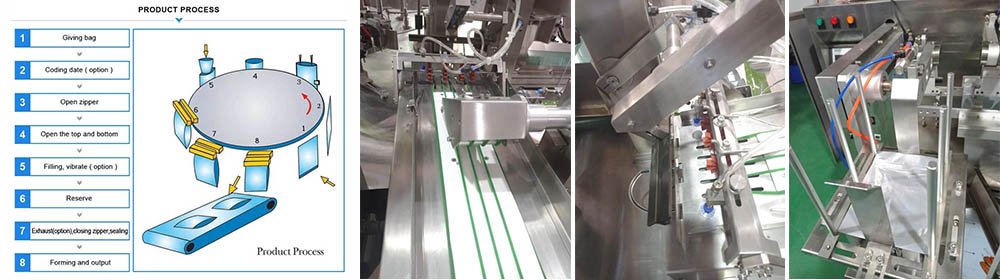

Packaging process:

1.Loading the bag: Put the bag flat on the horizontal bagging device or the vertical bagging device, the manipulator will automatically take the bag, and if there is no bag, it will automatically warn. Intelligent bagging can effectively reduce employment and labor costs. About vertical bagging device and horizontal bagging device:

Vertical bagging device: 1. Suitable for flat bags, 2. Suitable for smaller bags, 3. Suitable for more regular bags

Horizontal bagging device: 1. Suitable for bags of various shapes, 2. Suitable for bags of various sizes, 3. Suitable for irregular bags, 4. The width is easy to adjust, the best choice for bags of two or more sizes 5. Can put many bags

2.Print the production date: use the ribbon coding machine to code the bottom of the bag, mark the product name or production date, expiration diary or other, automatically check the use of the ribbon, automatically alarm when it is used up, and there will be a display on the touch screen to remind The staff will replace it in time to ensure that the code can be normally marked on the packaging bag.

3. Opening the zipper device: The installation of the zipper opening device can improve the success rate of opening the bag and effectively improve the packing efficiency.

4. Open the bag: Open the bag with a clip, and then drop the material, intelligent detection, if the bag is not successfully opened, the material will not be dropped, which can reduce material loss and ensure the cleanliness of the machine.

5. Filling hopper: If the bag has no material, it will not be sealed, which can ensure that the bag will not be wasted and reduce the production cost.

6.Reservation station: reserved for customers to add devices suitable for products, such as nitrogen filling, stabbing devices, etc.

7.Heat sealing: Use the temperature to heat seal the bag mouth. If the temperature is too low or too high, an abnormal temperature alarm will be displayed on the screen, which can maximize the sealing quality.

8.Cooling shaping and discharging: shaping the seal and then discharging to ensure the seal is beautiful and neat.