Cheetos (formerly styled as Chee-tos until 1998) is a crunchy corn puff snack brand made by Frito-Lay, a subsidiary of PepsiCo. Fritos creator Charles Elmer Doolin invented Cheetos in 1948, and began national distribution in the U.S. The initial success of Cheetos was a contributing factor to the merger between The Frito Company and H.W. Lay & Company in 1961 to form Frito-Lay. In 1965 Frito-Lay became a subsidiary of The Pepsi-Cola Company, forming PepsiCo, the current owner of the Cheetos brand.

In 2010, Cheetos was ranked as the top selling brand of cheese puffs in its primary market of the United States; worldwide the annual retail sales totaled approximately $4 billion. The original Crunchy Cheetos are still in production but the product line has since expanded to include 21 different types of Cheetos in North America alone. As Cheetos are sold in more than 36 countries, the flavor and composition is often varied to match regional taste and cultural preferences—such as Savory American Cream in China, and Strawberry Cheetos in Japan.

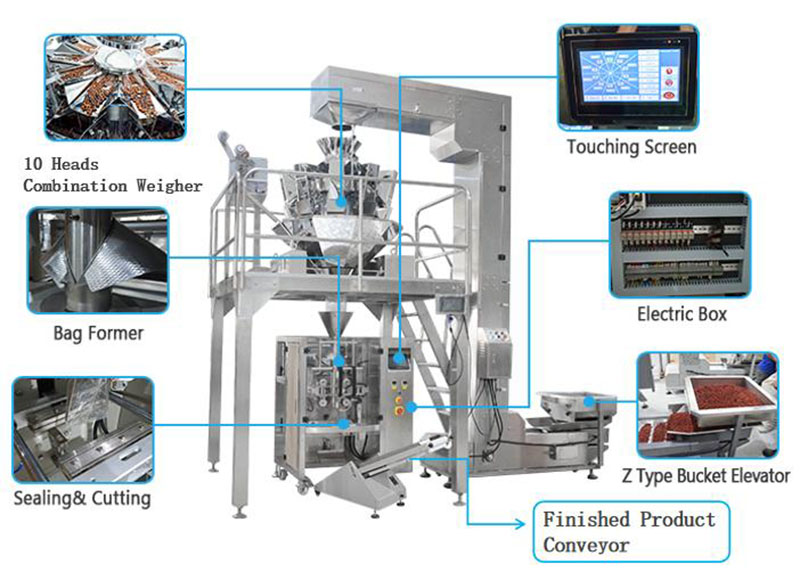

Foshan LANDPACK Packaging Machinery Co., Ltd. specializes in all kinds of packaging machinery for more than 15 years. Here we have rich experienced engineers and distributors. No matter what product you want to pack, we can always give you a satisfactory solution. The packaging bags of cheetos products are generally back-sealing bags, which can be packaged by our standard machine. One machine can basically be operated by 1-2 people, which can greatly reduce labor costs and improve packaging efficiency. The following machine is suitable for packaging Cheetos products:

The specific working principle: using the Z type bucket elevator to lift the product to the multi-head electronic combination weigher, enter the weight and speed you need to weigh on the combination scale, and the electronic scale will automatically start running. Its measurement accuracy is very high, which can reach 0.3 -0.5g

Here are some of the major components notation about this machine to aid understanding: Put the material on the Z-type bucket elevator, and the elevator will bring the material up, it can saving time and effort. We can see that there is a staircase on the right side of the support platform, its function is that our staff can go up to check the electronic equipment at any time. The condition of the materials on the scale is easy to maintain, and there are fences for higher safety. The one below is our main packer, which mainly packs the products into bags. Different bag width require different bag former. The length of the bag can be adjusted through the screen. , the finished product conveyor belt is an optional device that transports the products out and then sorts them, which can make the operation more flexible

Finished product display: