Model: LDSP-160

Filling Range: 10-200ml

Collocation: Liquid Metering Pump

Application: Liquid/ paste type: detergent, rice wine, soy sauce, rice vinegar, fruit juice, beverage, tomato sauce, peanut butter, jam, chili sauce, bean paste.

5-50bag/min

Model: LDSP-160

Filling Range: 10-200ml

Collocation: Liquid Metering Pump

Application: Liquid/ paste type: detergent, rice wine, soy sauce, rice vinegar, fruit juice, beverage, tomato sauce, peanut butter, jam, chili sauce, bean paste.

5-50bag/min

● Application: Personal care: liquid detergent, liquid soap, liquid washing detergent, liquid laundry detergent, etc; Foods: juice, edible oil, soy sauce, duck sauce, salad, mayonnaise, tomato ketchup, anchovy essence, cocktail sauce, barbecue sauce, hot sauce, etc.

● Easy and simple to put bags in the bag slot, equipped with automatic bag pressing device;

● Most parts are fabricated by mold production; the main material is 304 stainless and alumina;

● The machine is of SS304 appearance. Carbon steel frame and some parts are acid-resistant, salt-resistant anti-corrosion layer processed.

● Customized main machine structure for various kinds of bag shape. Like doypack zipper bag, 4 side seal bag, stand up bag and irregular bag, ect.

● With upgrade PLC control system, easy for operation on touch screen of parameter setting.

● Machine machine can equipment with different metering system like weigher, liquid pump, auger filler, bucket chain for different kinds of product filling and packing in premade bag.

Model | LDSP-160L |

Packing material | 3-side, four edge-sealing bag, self-reliance bag, handbag, spout bags, zipper bag, compound bag, etc |

size | W:100-210 mm |

Filling range | 10-1000g |

Packing speed | 10-45 bag/min(speed is determined by the product filling quantity) |

Average precision | ≤ ±1% |

Total power | 2.5KW |

Weight | 900 KG |

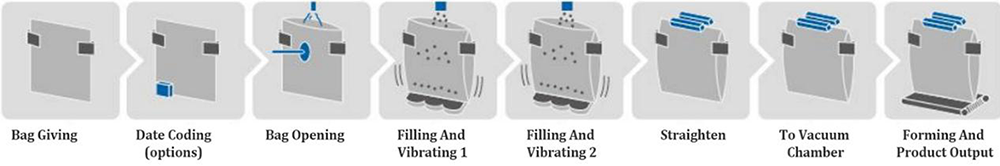

Main standard parts | 1. Code printer 2. PLC control system 3.Bag opening device 4. Vibration device 5.Cylinder 6. Electromagnetic valve 7. Temperature controller 8.Vacuum pump 9. Inverter 10. Output system |

● 1.Giving bag → 2.Pick up the bag(coding) → 3.Open the bag up and down → 4.Filling → 5.Heating sealing → 6.Output of product

After receiving your inquiry, We will send you the quotation as soon as possible.