Model: LDB-300A

Application: The machine is suitable for packaging granular materials, such as vegetable beans, coffee beans, potato chips, nuts, peanuts, cashews, etc.

0~15bags/min

Model: LDB-300A

Application: The machine is suitable for packaging granular materials, such as vegetable beans, coffee beans, potato chips, nuts, peanuts, cashews, etc.

0~15bags/min

● The machine is suitable for packaging granular materials, such as vegetable bean, coffee beans, potato chips, nuts, peanuts, cashews, walnuts, spaghetti, pet food, candy, gummy bears, beef cubes, popcorn, meatballs, dried fish, wolfberries, olives, dried fruits, tea, melon seeds, rice, etc.

● It is widely used in food, medicine, chemical, hardware, toys, and other industries. It can be used with various filling devices such as screw scales, linear scales, and a combination.

Packaging Material:

Vegetable Bean

Vegetable Bean

Vegetable Bean

Vegetable Bean

Vegetable Bean

Vegetable Bean

Bag Style:

Vegetable Bean Packing

Vegetable Bean Packing

Vegetable Bean Packing

Vegetable Bean Packing

Vegetable Bean Packing

Vegetable Bean Packing

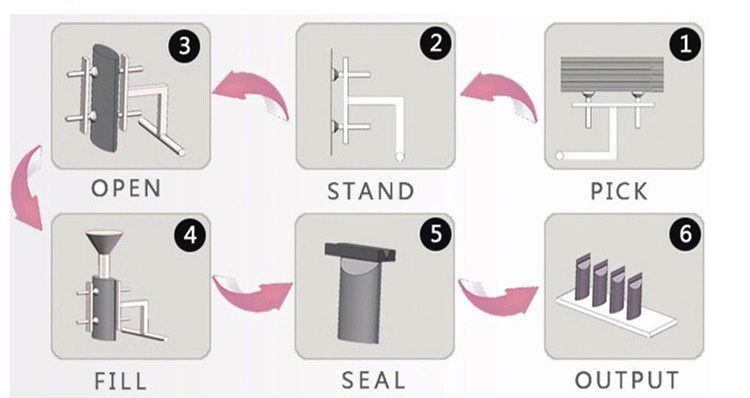

● BAG LOADING

The Pouch magazine is adjustable for the different-sized bags.

The Bags can be loaded while the machine is in operation

● BAG DETECTION

Multiple bag detection switches are used at various points in the cycle to ensure correct bag placement and full bag opening. Should a reject bag be detected it is ejected from the machine and the process continues. Rejected bags can be inspected by the operator and re-used if good.

● BAG OPENING

Pouches are individually removed from the cartridge with a unique combination of vacuum and pneumatic actuators. They are rotated/ transferred to the fill area and opened.

● TRANSITION CHUTE

doubling as a timing bucket. product enters the transition chute while the bag is being opened below. Upon pouch detection, the Chute/Funnel enters the bag and opens the gate. Product is dispensed immediately, without spillage and protecting the seal from contamination. The difficult product that easily bridges is dispensed into the pouch directly from the filler, through the "open-gate''

● FILLING

During filling, pouches are held in place with our “positive-hold” gripper system. This allows for heavyweights and shock loads without altering bag Position;

● SEALING

Digitally controlled ribbed or flat constant heat seal bars give an integral attractive seal. Pouches are sealed ''in place" eliminating wrinkles, folded corners, and non aligned seals

● MACHINE CONTROLS

System controls are fully solid state. utilizing a commercial Programmable Logic Controller [PLC] and Pneumatic. Indicator lights signal all cycle processes for easy monitoring.

Model | LDB-300A |

Bag Material | Multilayer Composite Premade Bag (e.g.: PET/PE) |

Bag Type | 3 Side Seal Bag, Stand-up Bag |

Upgradable Bag Type | Gusset Bag, Zipper Bag, Flat Bottom Pouch (Need additional purchase of functional device) |

Size Range | 80mm≤W≤300mm 100mm≤L≤300mm |

Speed | 0~15bags/min |

Sealing Type | Straight grain, the pitch is 1mm (Optional reticulate) |

Sealing Width | 10mm (5--20mm can be customized) |

Voltage | 220V, Single-phase, 50/60HZ, 1.2KW |

Air Pressure | 0.65Mpa |

Air Consumption | 0.3m³/min (Standard machine, no additional function) |

Body Dimension | 1770*600*1260mm |

Packing Dimension | 1860*710*1650mm (Export non-fumigation wooden case) |

After receiving your inquiry, We will send you the quotation as soon as possible.