Model: LD-8200A/ 8240A/ 8300A

Pouch Type: All type of heat sealable preformed side seal bags, gusseted bags, block bottom bags, zip-lock recloseable bags, stand-up pouch with or without spout etc.

Filling Volume: Filling Volume: 10-2500g

Packaging Accuracy: Error≤±1

25-60 bags/min

W: 100-300mm L: 100-450mm

Model: LD-8200A/ 8240A/ 8300A

Pouch Type: All type of heat sealable preformed side seal bags, gusseted bags, block bottom bags, zip-lock recloseable bags, stand-up pouch with or without spout etc.

Filling Volume: Filling Volume: 10-2500g

Packaging Accuracy: Error≤±1

25-60 bags/min

W: 100-300mm L: 100-450mm

●Suitable for automatic packing for grain nuts, such as walnuts, cashews, pistachios, almonds, peanuts, chestnuts, seeds, etc.

●Suitable Pouches: All type of heat sealable preformed side seal bags, fin seal bags, gusseted bags, block bottom bags, zip-lock recloseable bags, stand-up pouch with or without spout ect.

Packaging Material:

Chestnut

Cashew Nuts

Peanut

Macadamia

Pistachio

Almond

Bag Style:

premade pouch

premade pouch

premade pouch

premade pouch

premade pouch

premade pouch

● Automatic rotary packing machine adopt precision indexing device and PLC to control each action and working station to make sure the machine operates easily and does accurately.

● The speed of this machine is adjusted by frequency conversion with the range, and the actual speed depends on type of products and pouch.

● Automatic checking system can check bag situation, filling and sealing situation.

● The system shows

1.no bag feeding, no filling and no sealing.

2.no bag opening/opening error, no filling and no sealing

3.no filling, no sealing..

● The product and pouch contact parts are adopted stainless steel and other advanced material to guarantee the hygiene of products.

We can customize the suitable one for you according to your requiredment.

Just Tell us : Weight or Bag Size required.

● Model: LD-8200A/ 8240A/ 8300A

● Bag Size: W: 100-300mm L: 100-450mm

● Filling Volume: 10-2500g (Depending on type of products)

● Capacity: 25-60 bags/min (The speed depends on type of products and packaging material used)

● Package Accuracy: Error≤±1%

● Compress Air Requirement: ≥0.8m³/min supply by user

Optional configuration:

1. Material weighing & filling machines

2. Platform

3. Check weigher

4. Material elevator

5. Finished product conveyor

6. Metal detector

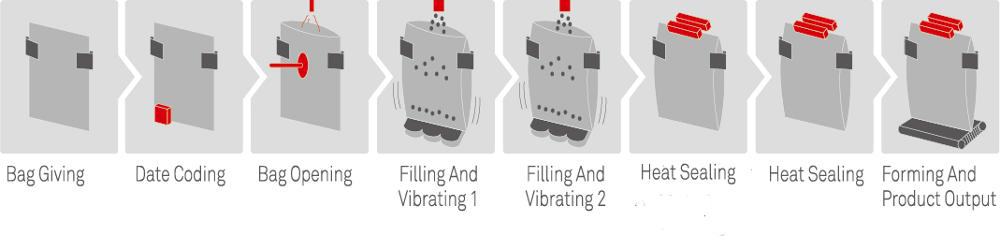

1. Bag giving

2. Date coding

3. Bag opening

4. Filling and vibrating 1

5. Filling and vibrating 2

6. Product settling after filling by vibrating

7. Heat sealing

8. Forming and product output

After receiving your inquiry, We will send you the quotation as soon as possible.