Model: LD-8200D/ 8240D/ 8300D

Average Precision: <±1%

Application: It is suitable for automatic packing for Powder: milk powder, coffee powder, food additives, condiments, tapioca powder, coconut powder, pesticide powder, fertilizer granules etc.

40-60 bags/ min

Model: LD-8200D/ 8240D/ 8300D

Average Precision: <±1%

Application: It is suitable for automatic packing for Powder: milk powder, coffee powder, food additives, condiments, tapioca powder, coconut powder, pesticide powder, fertilizer granules etc.

40-60 bags/ min

●Application: It is suitable for automatic packing for Powder: milk powder, coffee powder, food additives, condiments, tapioca powder, coconut powder, pesticide powder, fertilizer granules etc.

●Kindly Reminder: We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

●Full automatic intermittent rotary preformed bags dispensing, opening and closing machine combined with automatic auger powder filler, bulk screw feeder and product bulk hopper.

●Safety guard protected for high speed and consistent production heavy duty components and parts are selected for machine durability.

●Hygienic construction and easy cleaning operators friendly design touchscreen control system.

●Adopt advanced PLC, mate with touch screen and electric control system, the man-machine interface is friendly.

●Dust control and extractor system on special request.

●Automatic checking system can check bag situation, filling and sealing situation.

| Model | LD-8200D/ 8240D/ 8300D |

| Packing material | 3-side, four edge-sealing bag, self-reliance bag, handbag, spout bags, zipper bag, compound bag, etc |

| size | W: 100-300mm L: 100-450mm |

| Filling range | 5-2500g (Depending on type of products) |

| Packing speed | 25-60 bags/min (The speed depends on type of products and packaging material used) |

| Average precision | ≤ ±1% |

| Total power | 2.5KW |

| Dimensions | 1900mm X 1570mm X 1700mm(L*W*H) |

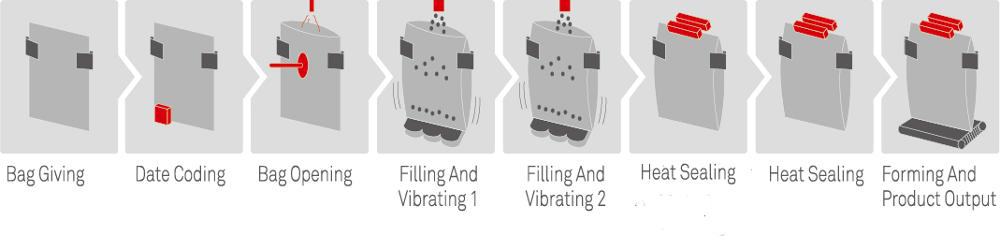

| Work flow | giving bag→coding →opening →filling 1 →filling 2→ auxiliary→ exhaust→heat sealing→ .forming and output product |

1. Bag giving

2. Date coding

3. Bag opening

4. Filling and vibrating 1

5. Filling and vibrating 2

6. Product settling after filling by vibrating

7. Heat sealing

8. Forming and product output

After receiving your inquiry, We will send you the quotation as soon as possible.