Model: LD-480YC-2

Application:

Suitable for a variety of granular products, such as granules, cereal, coffee, monosodium glutamate, sugar, salt, pills, desiccants, etc.It can be applied to liquid and powder products after replacing the metering device.

Customizable

Customizable

Model: LD-480YC-2

Application:

Suitable for a variety of granular products, such as granules, cereal, coffee, monosodium glutamate, sugar, salt, pills, desiccants, etc.It can be applied to liquid and powder products after replacing the metering device.

Customizable

Customizable

● Application: Multi Lane Packaging Machine And Cartoning Packaging System It is suitable for a variety of granular products, such as granules, cereal, coffee, monosodium glutamate, sugar, salt, pills, desiccants, etc.It can be applied to liquid and powder products after replacing the metering device.

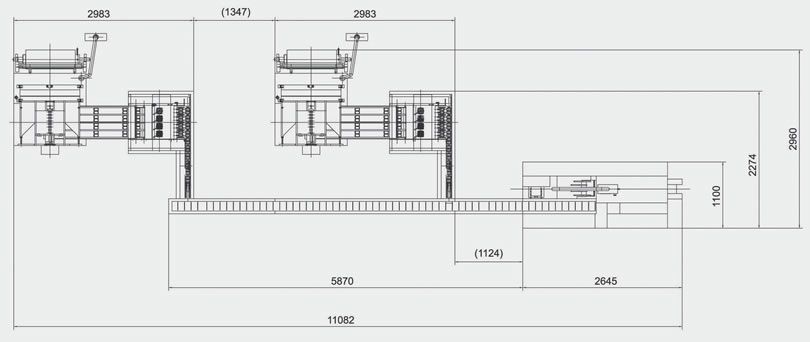

● 1. The packaging production line is mainly composed of a multilane packing machine, a small bag sorting conveyor, an electronic weighing machine, a weight sorting scale, and a cartoning machine.

● 2. In order to control accuracy and convenient adjustment, the main parts are controlled by servo motors.

● 3. It is suitable for automatic connection and boxing of 3/4 side sealing bags or stick pack. Online can complete automatic vacuum feeding, bag making, filling, batch numbering, cutting and tearing, bag-shaped punching, bag picking arrangement and transmission, single bag weighing, missing and less filling removal, automatic counting of finished bags, stacking and transferring, Manual folding, carton forming, finished product bag boxing, batch number imprinting, carton packaging, waste rejection, finished product output, product counting, etc. can be automatically completed.

● 4. Meet GMP production requirements, effectively save labor costs and production costs, and change the design plan according to the actual requirements of customers.

| Multilane Packing Machine | |

| Model | LD-480Y-2 |

| Pouch Length | 50-120 (adjustable) |

| Pouch Width | 50-105mm |

| Packing Speed | 60 time/min(depend by pouch size & materia) |

| Filling Capacity | 0.5-50ml |

| Application Film | PET/ AL /PE PET/PE NY/AL/PE NY/PE |

| Max Film Width | 900mm |

| Max Film Diameter | φ300mm |

| Film Core Diameter | φ75mm |

| Electric Source | 380v 50hz(do as customer's request) |

| Total Powder | 15kw |

| Overall Dimension | 2200*1700*2250(L*W*H) |

| Machine Weight | 1500kg |

| Packaging size | 1650*1500*2200(L*W*H) |

| Cartoning Machine Parameters | |

| Encasing Speed | 30-100 cartons/min |

| Carton - Quality Requirement | 250-350g/lifangmi (Base on sachet or pouch size) |

| Carton - Dimension Range (L*W*H) | (70-180)mm*(35*120)mm*(14-50)mm |

| Leaflet - Quality Requirement | 60-70g/㎡ |

| Leaflet - Unfolded leaflet specification | (80-250)mm*(90-170)mm |

| Leaflet - Fold range | 1-4 fold |

| Compressed air - Working pressure | ≥0.6Mpa |

| Compressed air - Air consumption | 200-240L/min |

| Power supply | 220V 50Hz |

| Motor supply | 1.1 kw |

| Machine dimension (L*W*H) | 3100*1100*1550mm |

| Machine weight | about 1400kg |

● The packaging production line is mainly composed of a multilane packing machine, a small bag sorting conveyor, an electronic weighing machine, a weight sorting scale, and a cartoning machine.

After receiving your inquiry, We will send you the quotation as soon as possible.