Model: LD-210SP

Pouch Type: All type of heat sealable preformed side seal bags, gusseted bags, block bottom bags,zip-lock recloseable bags, stand-up pouch with or without spout etc.

Filling Volume: 20-1000g

Packaging Accuracy:Error≤±1

20-50bag/min

Model: LD-210SP

Pouch Type: All type of heat sealable preformed side seal bags, gusseted bags, block bottom bags,zip-lock recloseable bags, stand-up pouch with or without spout etc.

Filling Volume: 20-1000g

Packaging Accuracy:Error≤±1

20-50bag/min

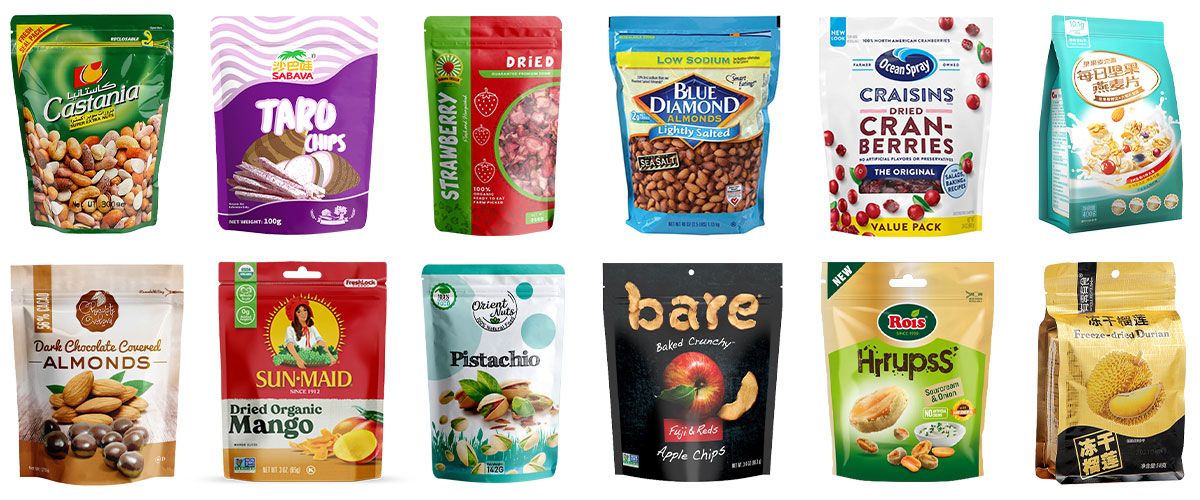

● It is suitable for weighing and packing grain, stick, slice, globose, irregular shape products such as puffy food, snacks,candy,jelly,seeds,almonds, chocolate, nuts, pistachio, pasta, coffee bean, sugar, chips, cereals, pet food, etc.

● Kindly Reminder: We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

● The machine completes the whole procedure of filling,measuring,bagging,date printing,charging(exhausting),produt out-putting automatically.

● High precision,high efficiency without crash the materials.

● New design with perfect fashion, more reasonable structure, more advanced technology.

● Imported PLC control system, colorful touch screen, easy operation, intuitionistic and efficient.

● Standard positioning with imported servo film transporting system and mark sensor, superexcellent capability for complete machine, perfect packaging.

● With auto warning protection function to minimize loss.

● Various kinds of bag, it could provide the pillow bag, angle fold bag, hang hole bag, link bag, etc.

● Automatic correct funtion, save time, labor and film, the operation more intelligent.

| Model | LD-160SP |

| Packing Speed | 20-50 bag/min |

| Total power | 380V,2.5KW,60Hz (Host) |

| Package dimensions | 80-160mm*110-230mm (Bag width * bag length) |

| Total Weight | 800KG |

| Packing capacity | 20g-500g |

| Air consumption | 0.7㎥/min |

| Bag type | All type of heat sealable preformed side seal bags, gusseted bags, block bottom bags,zip-lock recloseable bags, stand-up pouch with or without spout etc. |

● Work flow: The operator pours the materials into the vibrating plate, and configures as many vibrating plates as there are as many materials in a bag. The vibrating plate transports the materials to the conveyor belt, and transports the materials to the bag through the Z-type loader. Then, a series of links such as blanking, filling, coding, and sealing are carried out to complete the packaging process.

After receiving your inquiry, We will send you the quotation as soon as possible.